A brief history of waterproof jackets

For thousands of years mankind have been making items of waterproof clothing to keep their body dry. From animal skins and oiled cloths to scientifically developed materials, we take a look back at some of the ways in which this has been achieved.

Inuits lived in the sub zero conditions of the Arctic region and required clothing to keep them protected from the extreme elements. Whilst hunting for food in the treacherous ocean they needed an outer layer that would allow them to stay completely dry.

Never wasting any part of these hunts, they discovered that dried seal and whale intestines were waterproof, air-permeable (allowing sweat to escape), thin and light. The indigenous peoples also used the leftover bones to make glue that sealed the seams between layers of tissue.

Waterproof garments have always been needed for outdoor work, non more so than those at sea. Early mariners soaked heavy duty sailcloth with different mixtures of oil to make waterproof cape-like jackets.

This basic process evolved in the years that followed and the handmade ‘painting’ of sailcloth with a linseed oil mix eventually became an industrial process towards the end of the 18th century.

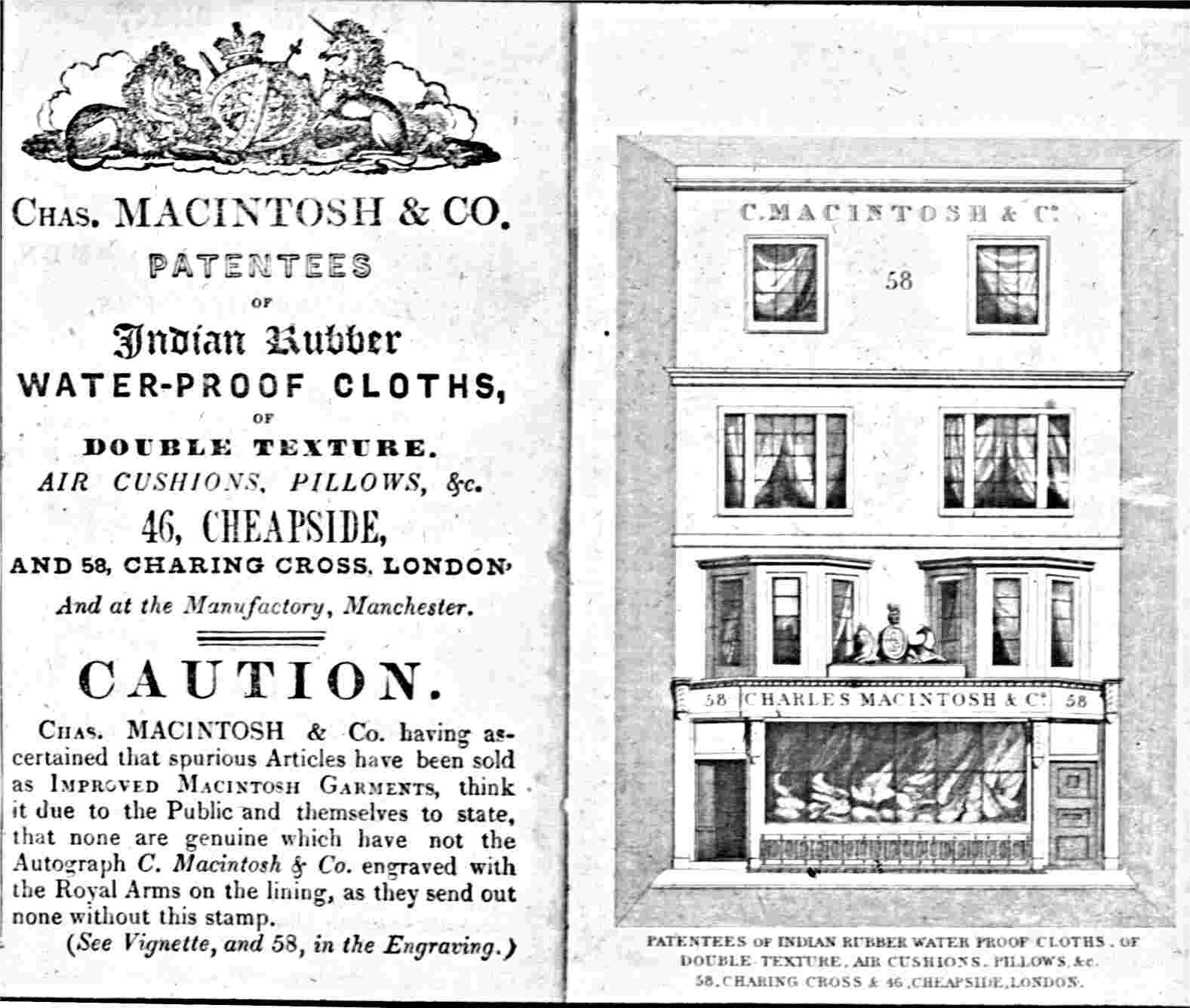

Manchester, with its large scale cotton industry, saw many developments in fabric technology and changed production methods for years to come. In the early 1800’s Charles Macintosh patented a double layered, textured material that was sandwiched around a thin layer of rubber, impervious to water and air. The Mackintosh jacket (the garment had a ‘K’ added) has since become iconic and paved the way for rainproof coats. Other local factories also used the material for producing some of the first ever ‘performance’ clothing lines for sports such as rowing, driving and shooting.

Other well known outerwear brands were also established in this period. In 1877 Helly Juell Hansen of Norway (Helly Hansen) used a waxed linseed oil to make comfortable seafaring clothing and in 1894 Barbour was formed in the North East of England making waxed workwear for fishermen, dock and shipyard workers.

Moving into the 1950’s & 60’s and with the advancement of synthetic materials such as PVC and Nylon, clothing brands starting producing cheaper, coated fabrics for the mass market. Pakamac was one of the most popular labels at the time and kept the rain and wind out but unfortunately also kept sweat in which became uncomfortable after long periods of wear.

By the 1970’s the race was one produce a jacket that had the right balance between performance, breathability, comfort and weight. That was until Bob Gore at the University of Delaware discovered expanded polytetrafluoroethylene (ePTFE) which he trademarked as GORE-TEX.

GORE-TEX is a thin membrane that repels water in droplet form but allows it to pass through as a vapour. This material has very little strength on it’s own so is sandwiched between an outer and inner layer, protecting it from abrasion and puncture and making the garment comfortable. This three-layer approach was the same as the Mackintosh raincoat launched decades before and is pretty much the same construction used in the majority of modern day technical jackets.

The outer layer of GORE-TEX or an equivalent material is coated in a Durable Water Repellant treatment to prevent the garment from soaking through and losing it’s breathable qualities. Under the GORE-TEX the inner layer is often a soft material allowing more comfortable movement against the skin and allows water vapour (sweat) to pass through unimpeded.

The challenge is now on to make the next big break through in waterproof material. Brands such as Voormi are working to drop the three-layered approach by weaving directly through a variety of water and wind proof membranes to create a uniformed layer that can achieve maximum comfort, insulation, wicking and weatherproofness in a lighter, more flexible garment.